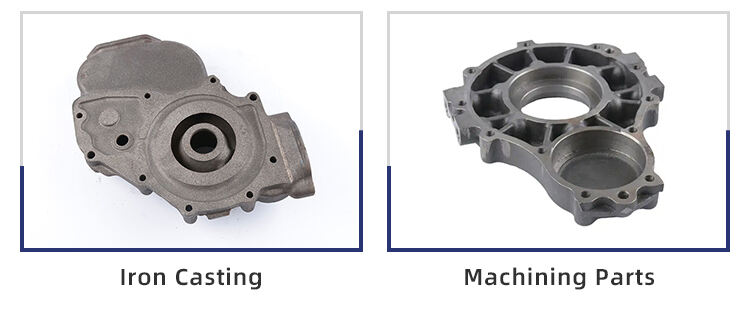

High Quality Custom Sand Iron Casting Services Foundry Roller Part Cast Iron Spare Parts Grey Iron Casting Cnc Machining G20

- Overview

- Parameter

- Features

- Inquiry

- Related Products

LF

The High Quality Custom Sand Iron Casting Services Foundry Roller Part Cast Iron Spare Parts Grey Iron Casting Cnc Machining GG20 ended up being proud to offer quality high casting provider for the roller part and additional components specifications. Our foundry try staffed by skilled professionals who focus on producing durable throw iron equipment utilizing the CNC machining. You'll be assured you choose a top-quality item that will perform reliably for a long period in the future whenever.

Afterwards you need a foundry that makes use of the most techniques up-to-date technology for producing iron customized if you're purchasing durable and roller dependable or equipment being free. Being strictly all you have as soon as you determineLFtop quality custom sand iron casting services. We utilize item quality to iron elements grey are greatest, and our professionals skilled the capability to build excessively accurate elements using our advanced CNC machining gear.

Our customized sand iron casting service are perfect for a selection of applications, like gear agricultural, and hefty commercial applications. We are able to create components solitary larger levels of throw iron elements, ensuring your shall have to help keep their operations running smoothly.

Often, criteria unique LF, we notice that every client has specifications. Being a total result of this reason great can get a variety of choices for the sand iron casting criteria. We could alter our cast iron elements considering your requirements being a remedy that try one-of-a-kind perfectly fulfills your preferences.

Our sand customized iron solution are not just very particular but excessively efficient. We use current CNC machining technologies to generate elements the bulk are accurate. This suggests that you will get their foundries off all on your own a product which try top-notch and in addition at an inferior cost.

In the event you require top-notch sand casting customized for the roller section or section contact LF High Quality Custom Sand Iron Casting Services Foundry Roller Part Cast Iron Spare Parts Grey Iron Casting Cnc Machining GG20. Most of us of skilled experts decided and ready to need the durable, dependable elements you need to keep their operations operating smoothly and you will be confident you are getting this product top-quality can play reliably for a while that's right was long on.

Product Name |

sand casting /grey iron casting / ductile iron casting /iron casting machining parts |

Casting Service |

sand casting, Horizontal line automatic molding, Resin sand molding |

Material |

GG20, GG25, GG30 / GGG40, GGG45, GGG50, GGG55, GGG60, GGG70 |

Tooling Design |

We have own R&D team, do DFM & Mode flow analysis |

Standard |

China GB high precision standard. / Non-standard customization |

Surface Finish |

Sand blasting, Mill Finishing, electrophoresis, galvanizing, Eco-friendly primer, Antirust oil |

Drawing |

3D Drawing: .step / .stp /.igs, 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp |

MOQ |

300kgs |

Q1 Are you a factory or trading company?A: We are a professional Foundry and Machining factory, and in the foundry industry for more than 20 years. We have own trading company.

Q2 How can I get the quotation quickly?A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you

earlier, please provide us the following information together with your inquiry. 1) 3D Step of Files and 2D Drawings. 2) Material requirement. 3) Surface treatment. 4) Quantity (per order/per month/annual). 5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3 What should we do if we receive defective products?A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q4 How to pack the mounds and products?A: 1). For molds, we will be coated one-layer anti-rust oil first, and then alill be covered thin films on the mold,

finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q5, can you make customized products?A: Yes, we mainly do customized products, we develop and produce products according to the drawings or samples provided by customers.

Q6 How will the goods be delivered to the customer?A: Use ship by sea. We are relatively close to Ningbo Port, so it is very convenient to export by sea. Of course, if the customer's goods are urgent, we can alhip by air. Ningbo Airport and Shanghai International Airport are very close to us.

Q7 Where do you mainly export your goods?A: Our products are mainly exported to dozens of countries such as Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8 What is normal process cooperation would you have?A: 1. We need the drawings for quote.

2.You accept the quotation and sign the contact, pay prepay 50% mold cost, we will start make the mold & handmake samples for approval. 3.You approve the samples and pay the 50% balance mold cost. 4.You send PO, pay us Advance, we arrange to manufacture and ship to you. 5.You Pay balance. 6.Received the products and feedback.

Q1 Are you a factory or trading company?A: We are a professional Foundry and Machining factory, and in the foundry industry for more than 20 years. We have own trading company.

Q2 How can I get the quotation quickly?A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you

earlier, please provide us the following information together with your inquiry. 1) 3D Step of Files and 2D Drawings. 2) Material requirement. 3) Surface treatment. 4) Quantity (per order/per month/annual). 5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3 What should we do if we receive defective products?A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q4 How to pack the mounds and products?A: 1). For molds, we will be coated one-layer anti-rust oil first, and then alill be covered thin films on the mold,

finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q5, can you make customized products?A: Yes, we mainly do customized products, we develop and produce products according to the drawings or samples provided by customers.

Q6 How will the goods be delivered to the customer?A: Use ship by sea. We are relatively close to Ningbo Port, so it is very convenient to export by sea. Of course, if the customer's goods are urgent, we can alhip by air. Ningbo Airport and Shanghai International Airport are very close to us.

Q7 Where do you mainly export your goods?A: Our products are mainly exported to dozens of countries such as Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8 What is normal process cooperation would you have?A: 1. We need the drawings for quote.

2.You accept the quotation and sign the contact, pay prepay 50% mold cost, we will start make the mold & handmake samples for approval. 3.You approve the samples and pay the 50% balance mold cost. 4.You send PO, pay us Advance, we arrange to manufacture and ship to you. 5.You Pay balance. 6.Received the products and feedback.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS