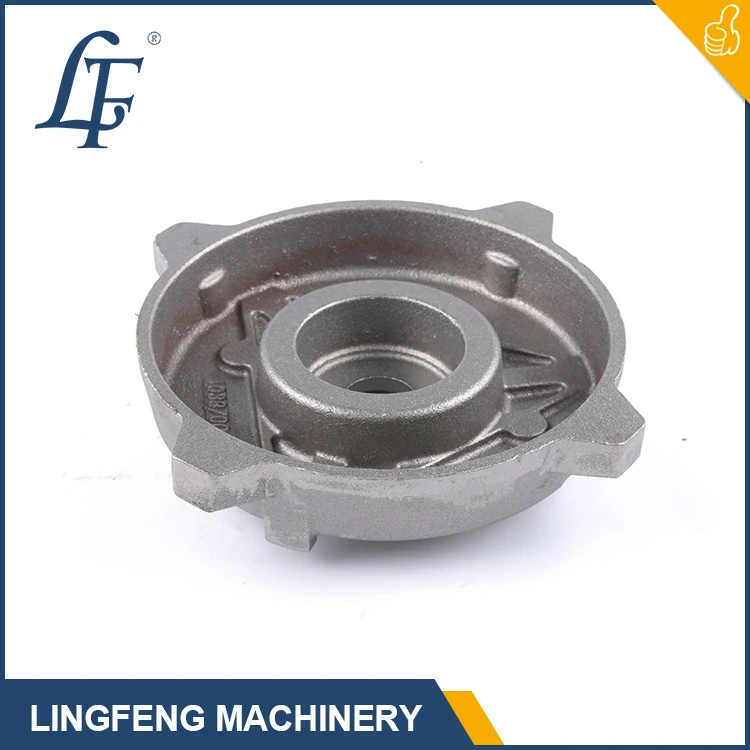

Motorflens Eindebedekking Aangepaste Gietijzer Gieterij Grijze IJzer Gieting Hoogwaardige Zandgietproducten FC200 FC205 FC300

- Overzicht

- Parameter

- Kenmerken

- Navraag

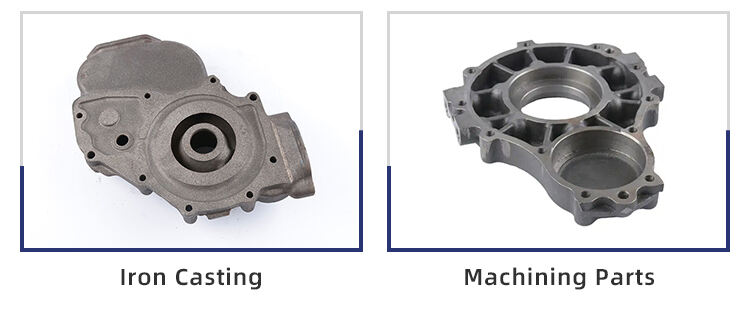

- Gerelateerde producten

Als

De Motorflange Eindebedekking Aangepaste Gietijzeren Gieterij Grauwe IJzeren Gieting Hoogwaardige Zand-Gietproducten FC200 FC205 FC300. De merknaam die leidt in aangepaste gietijzeren gieterijen, grauwe ijzeren gietingen en topkwaliteit zandgietproducten en vervaardigd uit topklasse producten duurzaamheid beter.

Ontworpen om een grondige hoeveelheid en versnelling te passen Als Motorflange deksel aangepaste gietijzeren gieterij grijs ijzer gieting hoge-kwaliteit zandgietproducten FC200 FC205 FC300 biedt een perfecte bescherming voor de flens en tegelijkertijd de motoras tegen vocht en schade van buitenaf. Het wordt een barrière die stof, vuil en andere ongewenste elementen tegenhoudt om in de motor te komen. Dit verlengt niet alleen de levensduur van de motor, maar garandeert ook een proces dat efficiënt, soepel en optimaal blijft.

Onze Motorflange einddeksel aangepaste gietijzeren gieterij grijs ijzer gieting hoge-kwaliteit zandgietproducten FC200 FC205 FC300 heeft een lichtgewicht en compact ontwerp wat de installatie en reparatie gemakkelijk maakt. De vorm is ontworpen om strak op de motorflans te passen, zorgend voor een stevige sluiting die elk lek voorkomt. Het doel is dat het onderdeel makkelijk te vervangen is, waardoor snelle reparaties en controle van de motor mogelijk zijn.

Bij LF gebruiken we een hoger gietniveau om zodanig topkwaliteit gieterijen te produceren die voldoen aan de eisen, over het algemeen zijn meeste eisen streng. We gebruiken zandgieten, een methode die authentiek is om de vorm te maken van een keuze aan zand en een binder. Dit proces levert nauwkeurige en gedetailleerde gieterijen op die consistent zijn in voldoening en kwaliteit.

Onze Motor Flange End Cover Custom Cast Iron Foundry Grey Iron Casting High-Quality Sand-Casting Products FC200 FC205 FC300 komen in verschillende maten en vormen om te voldoen aan verschillende flangemodellen en toepassingen. Of een type als soort zal worden voorgesteld door u dat probeert onze experts die professioneel aangepaste gieterijen bouwen die nauwkeurig aan hun behoeften voldoen.

Gevolglijk, als u op zoek bent naar betrouwbaar en duurzaam dat uw motor kan beschermen en de efficiëntie maximaliseert, kunt u meer verwachten dan LF. Met onze hoogwaardige gespecialiseerde gieterij, grijze ijsgieting en zandgietdiensten, kunt u ons vertrouwen om betere methoden te ontwikkelen die hun doelen vervullen of overtreffen. Bel ons voor meer informatie over onze motorflangegieterij met aangepaste einddekens van kastijzer. Grijze ijsgieting, hoge kwaliteit zandgietproducten FC200 FC205 FC300 en meer producten.

Productnaam |

zand gegoten / grijs ijzer gegoten / ductiel ijzer gegoten / ijzer gegoten machineren onderdelen |

Gegoten Service |

zand gegoten, Horizontale lijn automatisch vormgeven, Hars zand vormgeven |

Materiaal |

GG20, GG25, GG30 / GGG40, GGG45, GGG50, GGG55, GGG60, GGG70 |

Gereedschapsontwerp |

We hebben eigen R&D team, doe DFM & Mode flow analyse |

Standaard |

China GB hoge precisie standaard. / Niet-standaard aanpassing |

Oppervlakfinish |

Zandstralen, Mill Finish, elektrofose, galvaniseren, milieuvriendelijke primer, Antirust olie |

Tekening |

3D Tekening: .step \/ .stp \/ .igs, 2D Tekening: .dxf \/ .dwg \/ .pdf \/ .jpg \/ .tif \/ .bmp |

MOQ |

300kgs |

Vraag 1: Bent u een fabriek of een handelsbedrijf? Antwoord: Wij zijn een professionele Gieterij en Machineringfabriek, en hebben meer dan 20 jaar ervaring in de gieterijbranche. We hebben onze eigen handelsmaatschappij.

Vraag 2: Hoe kan ik snel een offerte krijgen? Antwoord: We sturen de offerte binnen 24 uur als we gedetailleerde informatie ontvangen tijdens werkdagen. Om u te kunnen offerteren,

zo vroeg mogelijk, geef ons alstublieft de volgende informatie mee met uw verzoek.

1) 3D Step-bestanden en 2D-tekeningen.

2) Materiaalvereisten.

3) Oppervlaktebehandeling.

4) Hoeveelheid (per bestelling/per maand/jaarlijks).

5) Eventuele speciale eisen of vereisten, zoals verpakking, labels, levering, etc.

V3 Wat moeten we doen als we defecte producten ontvangen? A: Als u een defect product ontvangt, stuur ons dan de foto's, we zullen dit doorsturen aan onze ingenieurs en QC-afdelingen en de problemen zo snel mogelijk oplossen.

V4 Hoe pakken we de modellen en producten in?

A: 1). Voor modellen zullen we eerst een laag antirroestolie aanbrengen, daarna zullen alle modellen met dunne folies worden bedekt,

en tenslotte inpakken in een geroete houten kist.

2). En wat betreft producten, zullen we deze inpakken in standaard export dozen of volgens klantenspecificaties.

V5, kunt u aangepaste producten maken? A: Ja, we richten ons voornamelijk op aangepaste producten, we ontwikkelen en produceren producten volgens de tekeningen of monsters die door klanten worden geleverd.

Q6 Hoe worden de goederen bij de klant bezorgd? A: Gebruik schip per zee. We zijn relatief dicht bij de haven van Ningbo, dus het is zeer gemakkelijk om per zee te exporteren. Natuurlijk, als de goederen van de klant urgent zijn, kunnen we ook vliegen per lucht. De luchthavens van Ningbo en Shanghai Internationale Luchthaven liggen heel dicht bij ons.

Q7 Waar exporteer je voornamelijk je goederen naartoe? A: Onze producten worden voornamelijk geëxporteerd naar tientallen landen zoals Duitsland, Japan, Spanje, Italië, het Verenigd Koninkrijk, Zuid-Korea, Australië en Canada.

Q8 Wat is het normale samenwerkingsproces dat je hebt?

A: 1. We hebben de tekeningen nodig voor een offerte.

2. U accepteert de offerte en tekent het contact, betaalt 50% voorschot voor de moldkosten, waarna we beginnen met het maken van de mold & handmatige monsters voor goedkeuring.

3. U keurt de monsters goed en betaalt de resterende 50% van de moldkosten.

4. U stuurt het purchase order (PO), betaalt ons voorschot, en wij regelen de productie en verzending naar u toe.

5. U betaalt de resterende saldo.

6. De producten ontvangen en feedback gegeven.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS