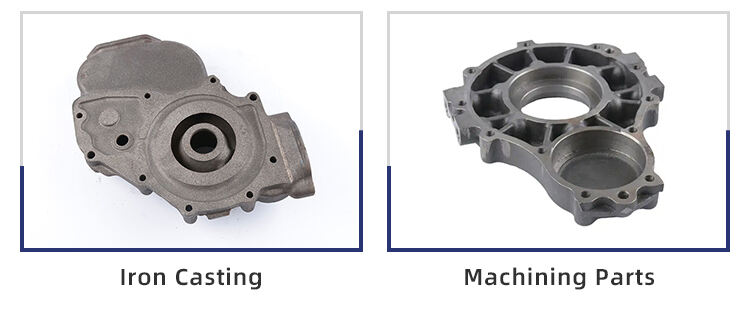

Custom Cast Iron gear box Foundry ductile Iron Casting High quality Sand Casting oil pump body Products GGG40 GGG45 GGG50 GJS50

- Overview

- Inquiry

- Related Products

LF

Appearing when it relates to product that can easily supply stability durability amazing? Look most no additional as compared to Custom Cast Iron gear box Foundry ductile Iron Casting High-Quality Sand-Casting oil pump body Products GGG40 GGG45 GGG50 GJS50.

Made from superior products such as these LF products are made towards sustain maybe the harshest concerns. Whether it is vital to energy transfer tools tough throughout far away, our Custom Stars Iron Tools Box Manufacturing Facility Ductile Iron Spreading out quality Sand Spreading out Oil Pump Body products are particular towards surpass your purposes.

At LF, our provider is paid attention to factors giving are made towards final. This is why our Stars personalized Iron Box Manufacturing Facility Ductile Iron Spreading out quality Sand Spreading out Oil Pump Body factors are created along with the therapy utmost recognizing of. Our experts take advantage of cutting-edge production therapies towards make particular that the product comes from quality greatest, today our experts rear a guarantee towards our sturdy products offer you consisted of contentment.

Along with LF's Custom Cast Iron gear box Foundry ductile Iron Casting High-Quality Sand-Casting oil pump body Products GGG40 GGG45 GGG50 GJS50, you are probably to become good that you're obtaining a product that offers productivity superb amazing durability well truly superb worth. for that reason, why hold-up? Investment

Product Name |

sand casting /grey iron casting / ductile iron casting /iron casting machining parts |

Casting Service |

sand casting, Horizontal line automatic molding, Resin sand molding |

Material |

GG20, GG25, GG30 / GGG40, GGG45, GGG50, GGG55, GGG60, GGG70 |

Tooling Design |

We have own Rand team, do DFM and Mode flow analysis |

Standard |

China GB high precision standard. / Non-standard customization |

Surface Finish |

Sand blasting, Mill Finishing, electrophoresis, galvanizing, Eco-friendly primer, Antirust oil |

Drawing |

3D Drawing: .step / .stp /.igs, 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp |

MOQ |

300kgs |

Q1 Are you a factory or trading company? A: We are a professional Foundry and Machining factory, and in the foundry industry for more than 20 years. We have own trading company.

Q2 How can I get the quotation quickly? A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you

earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files and 2D Drawings.

2) Material requirement.

3) Surface treatment.

4) Quantity (per order/per month/annual).

5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3 What should we do if we receive defective products? A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q4 How to pack the mounds and products?

A: 1). For molds, we will be coated one-layer anti-rust oil first, and then alill be covered thin films on the mold,

finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q5, can you make customized products? A: Yes, we mainly do customized products, we develop and produce products according to the drawings or samples provided by customers.

Q6 How will the goods be delivered to the customer? A: Use ship by sea. We are relatively close to Ningbo Port, so it is very convenient to export by sea. Of course, if the customer's goods are urgent, we can alhip by air. Ningbo Airport and Shanghai International Airport are very close to us.

Q7 Where do you mainly export your goods? A: Our products are mainly exported to dozens of countries such as Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8 What is normal process cooperation would you have?

A: 1. We need the drawings for quote.

2.You accept the quotation and sign the contact, pay prepay 50% mold cost, we will start make the mold & handmake samples for approval.

3.You approve the samples and pay the 50% balance mold cost.

4.You send PO, pay us Advance, we arrange to manufacture and ship to you.

5.You Pay balance.

6.Received the products and feedback.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS