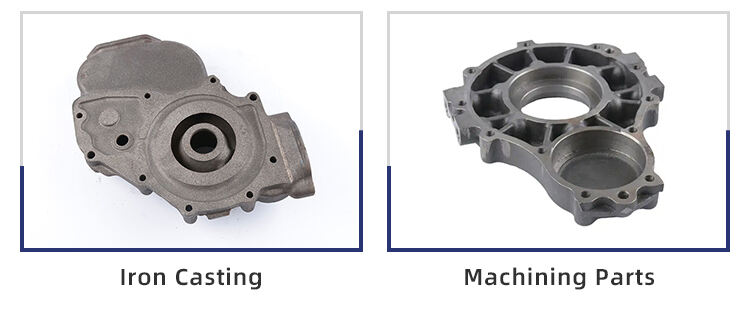

Grey Iron Casting High quality Motor end cover Sand Casting Custom Cast Iron Foundry flange cover GG20 GG25 GJL20 GJL25

- Overview

- Inquiry

- Related Products

The LF Grey Iron Casting High Quality Motor end cover Sand Casting Custom Cast Iron Foundry flange cover GG20 GG25 GJL20 GJL25. The flange cover is made using high-grade materials of GG20, GG25, GJL20, and GJL25. These materials ensure that the final product is of top-notch quality and durability, providing your motor with excellent protection.

The Grey Iron Casting Motor End Cover is sand-casted, which is a technique that enables this product to have a finish that is smooth exact proportions. This helps to ensure that the covers fit perfectly in your engine, providing protection against dirt, water, and other environmental elements.

The LF Grey Iron Casting Motor End Cover Sand Casting comes in different sizes. Being a customer, you merely need certainly to pick the many size that would work your motor model. They are going to create a special order for you personally if you demand a personalized size, consult the LF Custom Cast Iron Foundry, and.

The LF Grey Iron Casting Motor End Cover Sand Casting works with various motor models. Oahu is the item perfect shielding sensitive engine components from damage due to environmental elements, such as water and dirt. This product happens to be tested and which may offer stamina and protection that is long-lasting your motor.

The merchandise is manufactured making use of technology that is contemporary higher-level equipment, making certain the ultimate item is of quality, durability, and fulfills an individual's satisfaction. The LF Custom Cast Iron Foundry features a track record of creating personalized products which are top-quality and also the LF Grey Iron Casting Motor End Cover Sand Casting isn't any exception.

The LF Grey Iron Casting Motor End Cover Sand Casting is simple to install and maintain. The product does not need any know-how that is technical set it up on your own motor. Just a screwdriver and screws are essential to fix the covers. As soon as installed, this product calls for no upkeep that is additional, therefore saving maintenance expenses.

The LF Grey Iron Casting High Quality Motor end cover Sand Casting Custom Cast Iron Foundry flange cover GG20 GG25 GJL20 GJL25 could be the item that is perfect shielding sensitive and painful engine components from environmental damage. This product is of high quality, durability, and it is suitable for different engine models. It's not hard to install and keep maintaining, making sure your motor component remains well protected. Get the LF Grey Iron Casting Motor End Cover Sand Casting today, and feel the distinction it creates in protecting your engine.

Product Name |

sand casting /grey iron casting / ductile iron casting /iron casting machining parts |

Casting Service |

sand casting, Horizontal line automatic moulding, Resin sand moulding |

Material |

GG20,GG25,GG30 / GGG40,GGG45,GGG50,GGG55,GGG60,GGG70 |

Tooling Design |

We have own RandD team,do DFM and Mode flow analysis |

Standard |

China GB high precision standard. / Non-standard customization |

Surface Finish |

Sand blasting, Mill Finishing, electrophoresis , galvanizing, Eco-friendly primer, Antirust oil |

Drawing |

3D Drawing: .step / .stp /.igs, 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp |

MOQ |

300kgs |

Q1: Are you a factory or trading company?

A: We are a professional Foundry & Machining factory, and we have been in the foundry industry for more than 20 years. We also have our own trading company.

Q2: How can I get the quotation quickly?

A: We will submit the quotation within 24 hours if we receive detailed information during working days. To provide a quick quote, please share the following information with your inquiry:

3D Step Files and 2D Drawings.

Material requirements.

Surface treatment.

Quantity (per order/per month/annual).

Any special demands or requirements, such as packing, labels, delivery, etc.

Q3: What should we do if we receive defective products?

A: If you receive defective products, please send us photos. We will promptly involve our engineers and QC departments to address and resolve the issues.

Q4: How do you pack the moulds and products?

A:

For moulds, we apply a one-layer anti-rust oil coating first, then cover them with thin films, and finally pack them into fumigation wooden cases.

For products, we pack them into standard export cartons or customize the packaging based on customer requests.

Q5: Can you make customized products?

A: Yes, we primarily produce customized products. We develop and manufacture products according to the drawings or samples provided by customers.

Q6: How will the goods be delivered to the customer?

A: Usually, we ship by sea, considering our proximity to Ningbo Port. If the goods are urgent, we can also arrange air shipping. Ningbo Airport and Shanghai International Airport are convenient options.

Q7: Where do you mainly export your goods?

A: Our products are mainly exported to dozens of countries, including Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8: What is the normal process of cooperation?

A:

We need the drawings for a quote.

Upon accepting the quotation and signing the contract, pay a 50% prepayment for the mould cost. We will start making the mould and produce samples for approval.

After sample approval, pay the remaining 50% of the mould cost.

Send a purchase order, pay us in advance, and we arrange manufacturing and shipping.

Pay the balance.

Receive the products and provide feedback.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS