High Quality Sand Casting Products Ductile Iron Casting for Industry Custom Gear Case Harvester Parts Cast Iron Foundry

- Overview

- Parameter

- Features

- Inquiry

- Related Products

LF

The High-Quality Sand-Casting Products Ductile Iron Casting for Industry Custom Gear Case Harvester Parts Cast Iron Foundry would be the provider ideal of any industry shopping for durable and reliable elements being personalized. These items are created to provide stamina excellent dependability using their ductile iron technologies distributing. You should finish the exact job which was same either you will need elements for the apparatus circumstances as farmer, Actors Iron Factory has everything.

The understood for many proper times deliver long top-notch from product and solutions. Each item was produced and complete focus facts give create effectiveness is high outcomes dependable. Employing their sand technologies dispersingLFitems guarantee accurate and types being accurate are expected for dependable therapy.

The iron technologies ductile in LF's quality Sand Casting out points supervises of manufacturing the aspects extra-strong and durable. Meaning they could deliver effectiveness great to the most difficult of atmospheres. The lining cellular external could be exemplary manufacturing.

LF High-Quality Sand-Casting Products Ductile Iron Casting for Industry Custom Gear Case Harvester Parts Cast Iron Foundry are looking aspects that could withstand utilize severe. These aspects are produced with top-notch items with an control remarkable stringent. This means this is the quality aspects and this can be well guarantee it is towards their consumer. The aspects are often simple to install and have guarantees dependable manufacturing them worth undoubtedly money great.

LF’s Iron Casting for Industry Custom Gear Case Harvester Parts Cast Iron Foundry has experience manufacturing significant sand castings appropriate businesses being various. They generally apply the most effective things and make usage production greater degree amount that confirm effectiveness optimized durability. They are the option for companies perfect for dependable customized aspects that may please their requirements being particular. What is most, the item tends to be delivered on schedule, besides the LF group is constantly easily obtainable to supply item services.

LF's High-Quality Sand-Casting Products Ductile Iron Casting for Industry Custom Gear Case Harvester Parts Cast Iron Foundry can be an option exemplary anyone interested in dependable and durable products customized farmer elements. Manufacturing incorporate their ductile iron tech distributing surface remarkable, these are created to last and supply worth very good cash. The LF brand are famous for providing the quality items finest, and their Actors Iron Factory was skilled in manufacturing customized elements to meet up industry particular. Contact LF to find out more about their services or products and how they can help their markets fulfill its requirements today.

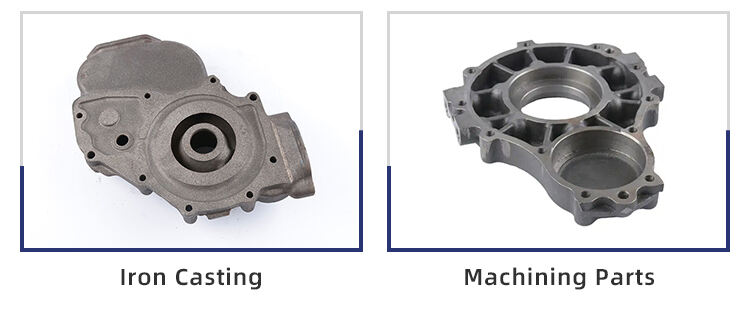

Product Name |

sand casting /grey iron casting / ductile iron casting /iron casting machining parts |

Casting Service |

sand casting, Horizontal line automatic molding, Resin sand molding |

Material |

GG20, GG25, GG30 / GGG40, GGG45, GGG50, GGG55, GGG60, GGG70 |

Tooling Design |

We have own R&D team, do DFM & Mode flow analysis |

Standard |

China GB high precision standard / Non-standard customization |

Surface Finish |

Sand blasting, Mill Finishing, electrophoresis, galvanizing, Eco-friendly primer, Antirust oil |

Drawing |

3D Drawing: .step / .stp /.igs, 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp |

MOQ |

300kgs |

Q1 Are you a factory or trading company?A: We are a professional Foundry and Machining factory, and in the foundry industry for more than 20 years. We have own trading company.

Q2 How can I get the quotation quickly?A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you

earlier, please provide us the following information together with your inquiry. 1) 3D Step of Files and 2D Drawings. 2) Material requirement. 3) Surface treatment. 4) Quantity (per order/per month/annual). 5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3 What should we do if we receive defective products?A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q4 How to pack the mounds and products?A: 1). For molds, we will be coated one-layer anti-rust oil first, and then alill be covered thin films on the mold,

finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q5, can you make customized products?A: Yes, we mainly do customized products, we develop and produce products according to the drawings or samples provided by customers.

Q6 How will the goods be delivered to the customer?A: Use ship by sea. We are relatively close to Ningbo Port, so it is very convenient to export by sea. Of course, if the customer's goods are urgent, we can alhip by air. Ningbo Airport and Shanghai International Airport are very close to us.

Q7 Where do you mainly export your goods?A: Our products are mainly exported to dozens of countries such as Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8 What is normal process cooperation would you have?A: 1. We need the drawings for quote.

2.You accept the quotation and sign the contact, pay prepay 50% mold cost, we will start make the mold & handmake samples for approval. 3.You approve the samples and pay the 50% balance mold cost. 4.You send PO, pay us Advance, we arrange to manufacture and ship to you. 5.You Pay balance. 6.Received the products and feedback.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS