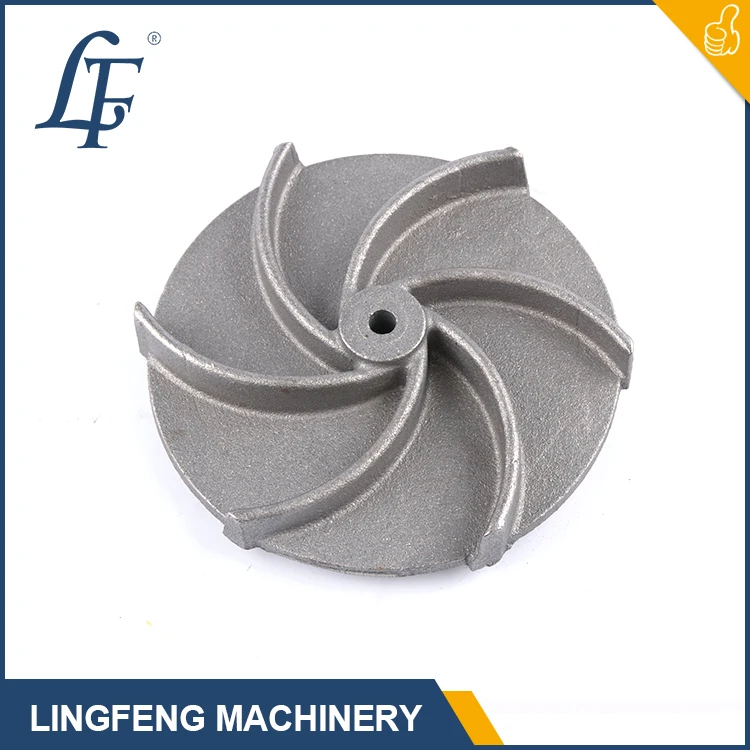

impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High quality Sand Casting GG20 GG25 CNC machining

- Overview

- Inquiry

- Related Products

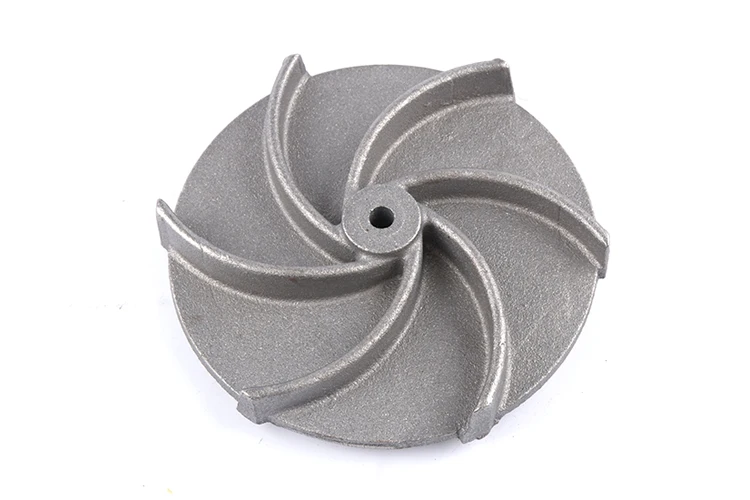

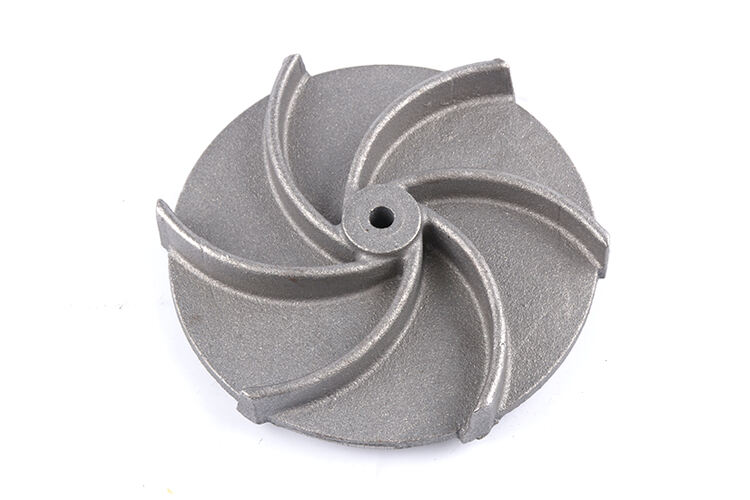

The LF impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining is a top-quality product by experienced professionals that are foundry. Using custom cast iron foundry GJL200 and GJL250 materials, our impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining are designed for longevity and durability. The grey iron and sand-casting processes found in the LF impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining's manufacturing make sure the finished item is of the highest quality.

Our impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining may function very well, assuring that every impeller arrives perfectly produced. Most of us understands the value of precision, which will be the reason why we utilize the most up-to-date equipment and tools to make sure that each impeller has no defects.

At LF, we realize that various customers have various requirements, which is why we offer custom impeller production to fit your requirements. You are able to offer us along with your desired dimension, form, and also other requirements, and we also shall use you to definitely do the job that can be particular.

The LF impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining is essential in various applications being industrial like the farming and mining industries, alongside to the marine and power industries. Our impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining can be employed in pumps, turbines, and also other heavy-duty machinery delivering excellent performance and durability.

The LF impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining performance metrics are great, having a top-notch deterioration opposition and exemplary reliability in most conditions. Our impeller Custom Cast Iron Foundry GJL200 GJL250 Grey Iron Casting High Quality Sand Casting GG20 GG25 CNC machining are resistant to effect, corrosion, oxidation and merely about every single other damage which are weather-related.

The LF team takes pride with its capacity to create top-notch impellers utilizing our substantial top-notch experience. We try to go beyond customers' objectives, providing on-time delivery and outstanding customer service from our devoted and skilled team.

Product Name |

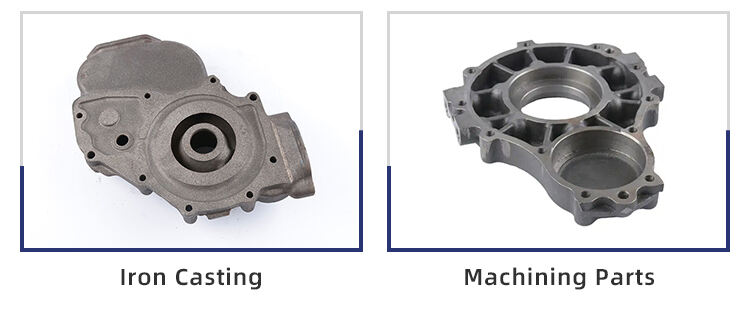

sand casting /grey iron casting / ductile iron casting /iron casting machining parts |

Casting Service |

sand casting, Horizontal line automatic moulding, Resin sand moulding |

Material |

GG20,GG25,GG30 / GGG40,GGG45,GGG50,GGG55,GGG60,GGG70 |

Tooling Design |

We have own R&D team,do DFM & Mode flow analysis |

Standard |

China GB high precision standard. / Non-standard customization |

Surface Finish |

Sand blasting, Mill Finishing, electrophoresis , galvanizing, Eco-friendly primer, Antirust oil |

Drawing |

3D Drawing: .step / .stp /.igs, 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp |

MOQ |

300kgs |

Q1: Are you a factory or trading company?

A: We are a professional Foundry & Machining factory, and we have been in the foundry industry for more than 20 years. We also have our own trading company.

Q2: How can I get the quotation quickly?

A: We will submit the quotation within 24 hours if we receive detailed information during working days. To provide a quick quote, please share the following information with your inquiry:

3D Step Files and 2D Drawings.

Material requirements.

Surface treatment.

Quantity (per order/per month/annual).

Any special demands or requirements, such as packing, labels, delivery, etc.

Q3: What should we do if we receive defective products?

A: If you receive defective products, please send us photos. We will promptly involve our engineers and QC departments to address and resolve the issues.

Q4: How do you pack the moulds and products?

A:

For moulds, we apply a one-layer anti-rust oil coating first, then cover them with thin films, and finally pack them into fumigation wooden cases.

For products, we pack them into standard export cartons or customize the packaging based on customer requests.

Q5: Can you make customized products?

A: Yes, we primarily produce customized products. We develop and manufacture products according to the drawings or samples provided by customers.

Q6: How will the goods be delivered to the customer?

A: Usually, we ship by sea, considering our proximity to Ningbo Port. If the goods are urgent, we can also arrange air shipping. Ningbo Airport and Shanghai International Airport are convenient options.

Q7: Where do you mainly export your goods?

A: Our products are mainly exported to dozens of countries, including Germany, Japan, Spain, Italy, the United Kingdom, South Korea, Australia, and Canada.

Q8: What is the normal process of cooperation?

A:

We need the drawings for a quote.

Upon accepting the quotation and signing the contract, pay a 50% prepayment for the mould cost. We will start making the mould and produce samples for approval.

After sample approval, pay the remaining 50% of the mould cost.

Send a purchase order, pay us in advance, and we arrange manufacturing and shipping.

Pay the balance.

Receive the products and provide feedback.

EN

EN

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ET

ET

TH

TH

MS

MS